Knife sharpening, pt.1

Edge Geometry

First off id like to start with saying there

is always more then one way to skin a cat and that cat is going to need a keen

edge to be skinned. There are thousands of variations on sharpening, I likely

have seen or used in reality variations in the dozens, From Lansky style tools

to $1000 sharpening machines, diamond hones to Japanese water stones that cost

more then you’re a wives anniversary present after a 7 year lapse of

anniversary presents.

First thing is first, to completely understand

what it is that makes a keen edge holding blade there are many factors involved

some I will go over here others not necessary to know for sharpening purposes.

Some of those factors are the type of steel, the heat treat of same steel and

edge geometry.

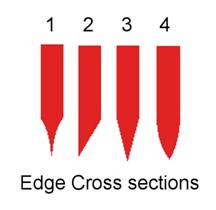

Edge Geometry, a somewhat fancy term for the

type of edge one has. There are 4 main types of edges with several variations

and combinations of such. Each with a specific type of

cutting action and use. Starting with the thinnest to thickest cut is..

1. Hollow grind:

2. Chisel grind

3. Flat grind

4.Convex, Also known as Saber and Apple seed grind.

Why is edge geometry so important? Because the geometry defines how a blade

will cut, is a factor in how easy it will be to sharpen and how well it will

hold an edge.

The Hollow grind

This type of edge is likely to produce the keenest

edge of all. It’s what is most common on straight razors for shaving. Little

more then a swipe on pants leg is needed to bring this edge back to life. It

dulls just as fast and more importantly it can chip very easily at the edge

which of course means it would need reground or at the least rehoned.

The Chisel Grind

This edge is a one sided edge and

has steel behind it on one side for strength yet a very fine flat zero

grind on the other for intricate shaving. Woodworker’s especially good ones

will have variations of this grind for specific tasks and interestingly enough

I found they have a high amount of sharpening knowledge due to varying styles

of chisels and hardness of woods. Many times their chisels are most guarded

tools.

The Flat grind

This

edge is probably the most common edge on any type of blade. It has steel behind

the edge to maintain a high degree of strength and depending on the angle of

the edge can be almost as sharp then a hollow grind yet due to having more

steel in it doesn’t wear the edge back as quickly or as much. Most of these

edges are between 20 and 17 degree set

The Convex grind

The old saber grind, although an axe grind should

be a better description of this as it’s a more common tool to have around the

house. The reason is although it can be a very sharp blade its main intention

is chopping. There is a lot of steel behind this edge and hence it holds a edge

the longest of all the edges, the drawback of this is it also makes the widest

roughest slice due that it pushes the cutting material apart as much as slices.

It also is one of the harder edges to sharpen correctly. (A side note is that

wives who haven’t had an anniversary acknowledged in 7 years tend to have a

special talent for this grind as they have hatchet in hand mulling this fact

over the day after her husband forgot the date again.)

Obviously although for the average

person maybe not so obvious is the thinner the edge and the steel supporting

that edge the finer the cut that can be made and following along with that is

the thinner the edge the faster it will lose that keen edge. Also it stands to

reason that the thinner the edge the less it takes to hone back to a keen edge.

Most people including folks who use blades a lot believe they really know how

to sharpen one up and I have seen many fine blade edges destroyed because they

didn’t understand really what was going on. A common issue is they tend to

believe that a honing or “sharpening stone is needed to sharpen when in fact

that’s the last thing most knife need. The main reason I say this is this, most

folks don’t consider the edge geometry and intended purpose and tend to not

have the skill needed to follow the geometry. I have seen untold folks

impressed that they can hone an edge to shave arm hair and then watched it dull

sometimes immediately as they used their fresh edge. Ill say

this several times in my writing probably so I may as well start here, SHAVING

ARM HAIR IS NOT A INDICATION THAT A EDGE IS SHARP. Ill explain why later

on in another part of the article.

As I said before there can be a combination of

bevels (side of blade) and edge on a blade. For instance a flat ground bevel

with convex or hollow grind edge, a hollow ground bevel with flat ground so on

and so forth. I believe in the K.I.S.S method of bladesmithing

in that I believe it’s better to make one or two styles very well then a wide

array of styles mediocre. As with everything mediocre skills produces mediocre

products and when income can be hindered or worse someone’s life is on the line

and that person has something I made in their hand, Id rather be good then

lucky.